MRI 3-Axis Gradient Coils

Clear bore 23.6 mm

Partially assembled three-axis gradient coils

- Active shielding

- B0 eddy current compensation

- Maximum Sample Volume

- Low Noise and Vibration

- High Continuous Gradients

Advances in hardware for magnetic resonance imaging (MRI) are needed to improve image quality, ease of use and functionality in high-field MRI research using small objects. Doty’s MRI gradient coils fill this need.

Low-amplitude B0 eddies are induced in the magnet radiation shields primarily from minute variations in coil diameters along the axis or from axial registration errors between the gradient and shield coils. Our use of alumina ceramic for both the gradient and shield formers allows higher precision to be maintained, and low-amplitude eddy current to be minimal. Ceramic coil forms, together with heavy Golay windings dramatically reduce vibration and noise, even at the highest fields. Any remaining B0 eddy is compensated by a time-dependent correction applied to a B0 shim coil. Another advantage of the alumina coil form is its very high thermal conductivity, which helps equilibrate hot spots. The cooling requirements are then satisfied with relatively minor constraints on the winding geometry.

Higher-order eddies are minimized by active shielding. Our coil designs often achieve a factor of 2 better shielding of the transverse gradients than alternative designs.

There is a strong benefit from gradient coil construction with an alumina ceramic coil form and multilayer windings. We significantly reduce acoustic noise, vibration and recovery time compared to gradient coils from other microscopy MR vendors.

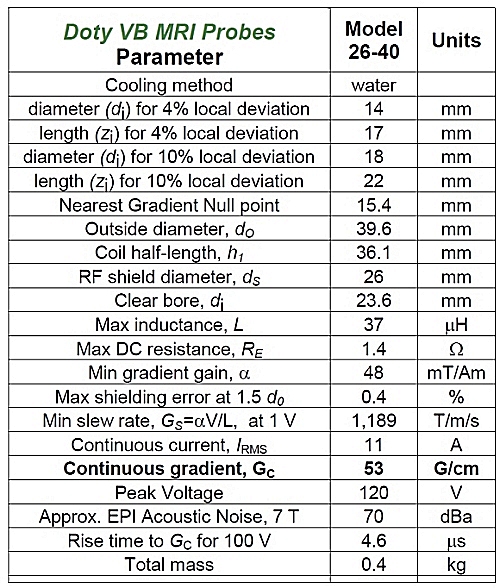

The performance for the X and Y axis are each as indicated in the table above, however, the Z axis is typically better in slew rate, continuous gradient, and volume of linear region than the above table indicates.

Local deviation (or differential linearity) is defined as the rms deviation from the mean gradient over the specified diameter, di, and length, zi, of the cylindrical sample region. The half-length h1 is the distance from the center to the closer of the two external end surfaces. Eddy currents from the internal RF shield are negligible. The gradient slew rate GS is the instantaneous rate of change in gradient when a 1 V step is applied. The continuous current ratings are true continuous ratings for a single axis with no time limit and adequate cooling. Derate the current 30% when all three axis are driven simultaneously.

**MRI COILS

Doty NMR/MRI

Please contact sales with questions or quote requests.