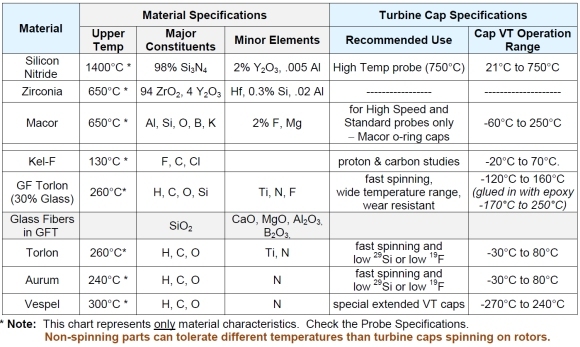

Doty spinners utilize super-precision, wear-resistant ceramic stators of silicon nitride or zirconia. MAS spinner materials must be chosen carefully based on background signals and temperature ranges. Ceramic rotors and plastic caps of various materials are available to provide fast spinning with limited background problems. For printable pdf, click here.

Spinner Assembly Materials – Plastics

Note: Torlon and GFT caps have some moisture absorption. It may be periodically necessary to bake out the turbine caps or tip caps at 50oC for one hour. This is necessary if the caps become too tight. (The opposite condition is much less likely. However, if one is in a very arid area or operating in a low moisture environment, the caps may have to be soaked in a liquid too make them tighter.) Glass Filled Torlon (GFT)caps are used for extended temperatures.

GFT (Glass-fiber-reinforced Torlon): Glass-fiber-reinforced Torlon grade 5030 will be used for some MAS turbine caps for greatly improved VT performance and all-around better reliability and performance. This new material stands out from the rest with respect to isotropic thermal expansion (only 16E-6/°C), tensile strength at 200°C (120 MPa), and heat distortion temperature (282°C). It also has rather high wear resistance, and high impact strength. These caps are the most wear resistant and have the widest temperature range. GFT is not recommended for proton studies, or for some silicon and some carbon studies. Caps may be used from -120°C to 160°C repeatedly (or when glued in with epoxy from -170°C to 250°C).

Torlon: Torlon is used for fastest spinning of DI3 turbines. This green thermoplastic polyamide-imide, has exceptional chemical resistance. Caps may be used from -30°C to 80°C repeatedly. The caps may be used once to higher temperatures but they will be too loose after that. (In non-spinning parts of the spinner assembly, the upper temperature limit is 260°C.) Torlon is not recommended for proton studies or for some carbon studies.

Kel-F: A translucent white plastic, Kel-F is background free for all nuclei except F, Cl, and C. Kel-F is also excellent for carbon studies since the strong fluorine coupling effectively broadens the Kel-F carbon signal, and there are no protons to cross polarize. Kel-F is not as strong or wear resistant as the other cap materials and is thus restricted to lower spinning speeds. Kel-F turbine caps can be used at temperatures from -20°C to 70°C. (In non-spinning parts of the spinner assembly, the upper temperature limit is 130°C.)

Aurum*: This material is no longer available in appropriate form for our manufacturing, so Aurum is being replaced by Torlon. Aurum will be supplied if requested and is available, but supplies are severly limited.

This dark brown to black thermoplastic polyimide has excellent dielectric properties. Aurum can be used for low silicon applications when fast spinning is desired. Aurum is supplied for some probes designed for fluorine studies and other applications where carbon is not a problem. Turbine caps may be used from -30°C to 80°C repeatedly. (In non-spinning parts of the spinner assembly, the upper temperature limit is 240°C.)

Vespel: This brown plastic is used for some extended temperature caps and for non-spinning spinner assembly parts that will reach temperatures over 200°C. Vespel is not recommended for proton studies or for some carbon studies.

O-Ring Caps

For wet samples, air sensitive samples, and variable temperatures

O-ring Caps: Turbines and plug caps with dual Viton o-ring seals are available for Macor, silicon nitride, and zirconia rotors. Macor rotors, (available only for standard and high speed probes) are recommended for wet samples, air sensitive samples, and temperatures from -60°C to 250°C. A single (rear) cap with o-rings is used with a Macor rotor. However, if faster spinning is critical, VT and air-sensitive experiments can be done in silicon nitride or zirconia rotors using o-ring-sealed cap pairs. O-ring turbine caps are normally inserted and removed by hand. Turbines with threaded holes can be ordered with a threaded insertion tool for use when loading samples in a glove box (and to remove standard speed plug caps.) Caps can be ordered with axial out-gassing holes for higher temperature work or to remove air bubbles.

Although the supersonic o-ring caps can be used for air sensitive samples in XC5 and XC7 probes, XC sealing cells are usually preferred.

- Kel-F O-ring Caps: …………………………… Temperature range with o-rings: -45°C to 80°C.

- Aurum or Torlon O-ring Caps: …………… Temperature range with o-rings: -45°C to 120°C.

Extended Temperature Caps

- DI, XC4 and XC5 probes (and most supersonic) use Glass-fiber-reinforced Torlon (GFT) – glued in.

GFT – if glued in: ………… Temperature range: -170°C to 250°C

* Torlon is replacing aurum for most parts, depending on availability. Torlon can be used as a substitute for aurum as the NMR characteristics are similar.

_________________________________________________________________________________________

Spinner Assembly Materials – Ceramics

Silicon Nitride: With a density of about 3.18 g/cm3 and a (working) tensile strength of 700 MPa, silicon nitride has the highest strength-to-weight ratio of any ceramic available today. Its hardness and toughness make it very difficult to grind, but it has the lowest dielectric loss and lowest permittivity of any engineering ceramic, making it the best choice for high frequencies. A HIPed (Hot Isostatic Pressed) variety is available with improved strength and dielectric properties. Its superior electrical properties make it the preferred material for most applications (often, even for silicon and nitrogen), because of silicon’s long T1 and nitrogen’s low natural abundance. The color is black. The only additive or impurity greater than 200 ppm in this new material is yttria. Silicon nitride stators, housings, and rotors are available in all sizes. This material is required for fastest spinning.

Zirconia: This yttria-stabilized, high-purity material is glossy white and has a density of about 6 g/cm3 and a (working) tensile strength of 700 MPa. Alumina content can be kept below 100 ppm. Zirconia is less expensive than silicon nitride, but the safe spinning speed for zirconia rotors is lower than that of silicon nitride.

Macor: This white, machineable, boro-silicate glass-ceramic is loaded with synthetic mica to inhibit crack propagation. It is easily machined with conventional tooling. Macor housings may be provided for carbon and proton studies at temperatures over 160°C in our standard speed MAS probes. Macor is useable up to 650°C, but it has very poor thermal shock tolerance. Macor rotors are only available for the high speed and standard spinners. Macor rotors are made with a thicker wall and are machined with an integral turbine at one end. Standard speed rotors require a plug-cap at the open end, while high-speed rotors require a rear turbine. Macor rotors are recommended for wet samples, air-sensitive samples, and temperatures from -150°C to 250°C. Major constituents: Al, Si, O, B, K, F.

Boron Nitride: Boron Nitride is not used in Doty probes. However, the hexagonal hot-pressed variety, with 6% calcium borate binder, is easily machineable and is used for disposable inserts for the high-temperature ceramic rotors for the Doty high temperature probe (700oC). The material is soft enough to scratch easily and may absorb up to 1% moisture.